A Superfund site is

an area designated by the United States Environmental Protection Agency (EPA) that

have been classified as being heavily contaminated with hazardous substances. These

substances may include chemicals, pollutants, or other toxic materials that

could have a significant risk to human health and the environment.

How Superfund site was created

According to the Environmental Protection Agency (EPA), "In the late 1970s, toxic waste dumps, such as Love Canal and Valley of the Drums, received national attention when the public learned about the human health and environmental risks posed by the contaminated sites. In response, Congress established the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) in 1980." This law was created to enforce the responsibility of parties involved in contamination to clean up the sites or compensate the government for EPA's cleanup efforts. In cases where no responsible party is identified for the cleanup or reimbursement, the EPA assumes responsibility for cleaning up the contaminated area. The CERCLA act is commonly referred to as a Superfund Site.

CERCLA Act

According to the EPA “The Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), commonly known as Superfund, was enacted by Congress on December 11, 1980. This law created a tax on the chemical and petroleum industries and provided broad Federal authority to respond directly to releases or threatened releases of hazardous substances that may endanger public health or the environment. Over five years, $1.6 billion was collected and the tax went to a trust fund for cleaning up abandoned or uncontrolled hazardous waste sites."

The purpose of CERCLA

According to the EPA: The Comprehensive Environmental Response, Compensation, and Liability Act of 1980 (CERCLA):

· established prohibitions and requirements concerning closed and abandoned hazardous waste sites;

· provided for liability of persons responsible for releases of hazardous waste at these sites; and

· established a trust fund to provide for cleanup when no responsible party could be identified.

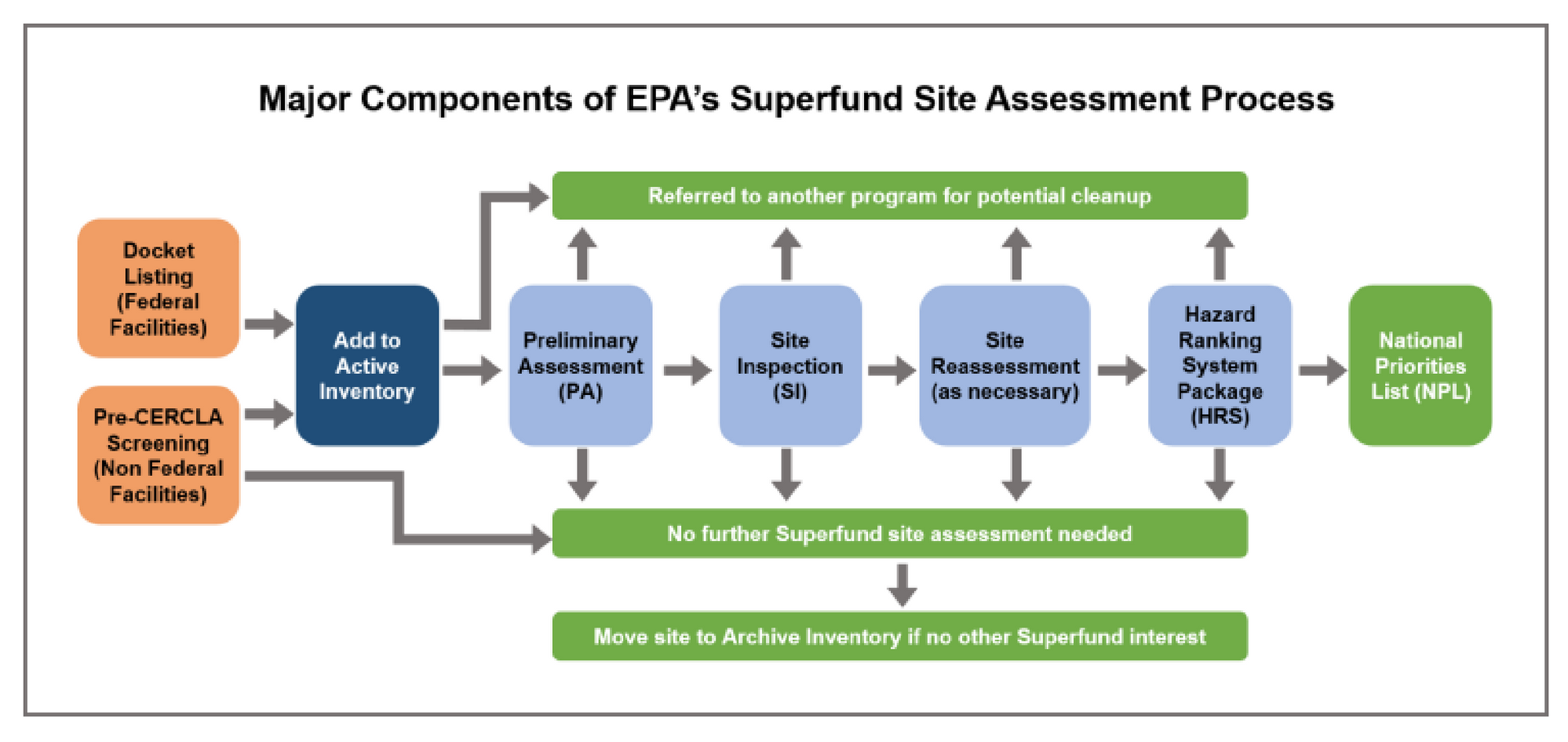

How Superfund site are chosen

According to the EPA, sites are chosen by “Using Hazard Ranking System (HRS) criteria, EPA, its state and tribal partners, or the appropriate federal department or agency then conduct a preliminary assessment and, if warranted, a site inspection or other more in-depth assessment.” Sites that have a HRS score below 28.50 do not qualify for the National Priorities List (NPL) and are assigned to a No Further Remedial Action Planned (NFRAP) decision.

CTI offers safety consulting and the cleanup of sites and contaminated locations. If you have questions or comments, call CTI at 562.608.8401 or email info@ctienviro.com.

Citations:

References available, upon request please contact us.

Cleaning up land, air, and water from hazardous waste

Many sites across the country are harmed by hazardous materials and waste from spills, leaks, accidents, and improper handling of dangerous materials. This has affected and contaminated the land, water, and air. Because of this, EPA and its state and territorial partners have developed cleanup programs.

Information about EPA Cleanups

The EPA manages and supervises investigations and cleanup programs on specific sites where oil or potentially hazardous chemicals are released. These cleanup programs can place on abandoned waste sites, federal facilities, and properties, and any storage tanks that have leaked. The EPA has many programs that are partnered, listed on their website:

- Emergency Response: when the danger from pollutants poses an immediate threat to human health or the environment

- Superfund Cleanup: for large, abandoned hazardous waste sites

- Federal Facilities Cleanup: for cleanups at facilities owned by the federal government (includes Superfund and RCRA sites)

- Brownfields Cleanup: for assessments and cleanups grants related to potentially usable properties

- Underground Storage Tank Cleanup: a state-delegated program for cleanups involving underground storage tanks

- RCRA Corrective Action: a state-delegated program for hazardous waste management facilities with a spill or release

- Cleaning Up Oil Spills: for spills of oil on land and in inland waters

- Cleaning Up Air Pollutants: for addressing releases of pollutants to the air

- Cleaning Up Water: to check on the quality of your waterways and learn about drinking water standards and where to find information about the quality of your drinking water

Click here to read more about each cleanup program

Cleanups: How you can help and get involved

If you are interested in helping clean up the community and environment, the EPA has many ways for you to get involved. This section will cover a couple of the programs and not all. To get a full listing, click here.

- Community Engagement and the Underground Storage Tanks Program

- Community Involvement at Engagement at Federal Facilities

- Community Involvement During Emergency Responses

- Sustainable Materials Management

- Public Participation in the Hazardous Waste Permitting and Corrective Action Processes

- Environmental Justice

Greener Cleanups

According to the EPA website, “a greener cleanup achieves remedial objectives for a contaminated site while decreasing the environmental footprint of cleanup activities.” The idea of a greener cleanup is a sustainable approach for cleaning up potentially hazardous and contaminated sites. Cleaning up these contaminated areas requires expending energy, water, and natural resources. The EPA created greener cleanups to protect the environment by optimizing the performances of cleanup technologies, fieldwork, educating about environmental footprints of cleanup projects, and minimizing those footprints while maximizing the ecological outcomes.

Greener cleanups help meet the goals of Executive Order 13834 Regarding Federal Operations. This order “requires agencies to make the Federal Government’s operations more sustainable…greener cleanup strategies in the U.S. EPA’s Superfund and other site cleanup programs help meet statutory requirements concerning energy and environmental performances.”

Greener cleanups can be used during emergency response, site investigation, evaluation of cleanup options, design, construction, and operation of a remedial project, long-term monitoring of a remedy, and site reuse planning.

Learn more about greener cleanups here.

Regulatory and Legal Information

The Resources Conservation and Recovery Act (RCRA) is a state delegated program including solid and hazardous waste management and corrective action when a hazardous waste accident occurs. RCRA takes effort when hazardous waste is contaminating a site. Depending on the nature of the violation and site circumstances, the type of RCRA approach will be decided. There are five RCRA Corrective Action Enforcement Actions according to the EPA.

- Administrative Actions

- Regulations Governing Administrative Actions

- Civil Judicial Actions

- Criminal Actions

- Citizen Suits

RCRA protects the environment as well as human health in several ways. Prevention and corrective planning. Prevention is “preventing future environmental problems from being caused by waste.” Whereas disciplinary action is “cleaning up current environmental problems caused by the mismanagement of waste.” According to the EPA, RCRA Subtitle C provides a system for managing hazardous waste from the time it is generated until its ultimate disposal. This regulation sets criteria and enforcement of the correction action and cleanup.

Learn more about the RCRA enforcement here.

Superfund/CERCLA Basics

The Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) is also known as Superfund and was enacted by Congress on December 11, 1980. According to the EPA, this law created a tax on the chemical and petroleum industries and provided broad Federal authority to respond directly to releases or threatened releases of hazardous substances that may endanger public health or the environment. There are three primary keys to this law, according to the EPA website,

- Establish prohibitions and requirements concerning closed and abandoned hazardous waste sites

- Provide for liability of persons responsible for releases of hazardous waste at these sites

- Established a trust fund to provide for cleanup when no responsible party could be identified

There are two response actions to take:

- Short-term removals: actions require prompt response

- Long-term remedial response actions: significantly reduce dangers associated with releases of hazardous substances that are serious

Information for Professionals

There are several cleanup grants that are available for different phases of the cleanup process. The EPA lists four programs that help with funding and supports the training process:

- EPA Grants

- The EPA works with partners to identify financing mechanisms supporting environmental programs and policies.

- Technical Assistance Grants (TAGs) Program:

- provides money for activities to help communities decision-making eligible Superfund sites.

- Superfund Job Training Initiative (SuperJTI)

- supports job-training programs in communities affected by nearby Superfund sites and encourages the employment of trainees at local site cleanups.

- Types of Brownfields Grant Funding

- EPA’s Brownfields Program provides direct support for brownfields assessment, cleanup, revolving loans, and environmental job training.

If you are interested in training, The Training Exchange provides 19 videos and courses that have to do with a cleanup.

Citations:

https://www.epa.gov/greenercleanups/learn-about-greener-cleanups

https://www.epa.gov/enforcement/types-and-approaches-rcra-corrective-action-enforcement-actions

https://trainex.org/catalog/bymethod_view.cfm?media=Streaming%20Video%20Presentation

What is Hazard Communication Standard?

According to OSHA, “in order to ensure chemical safety in the workplace, information about the identities and hazards of the chemicals must be available and understandable to workers.” The Hazard Communication Standard (HCS) by OSHA calls for the “chemical manufacturers and importers to evaluate the hazards for the chemicals they produce or import, and prepare labels and safety data sheets to convey the hazard information to their downstream customers.” It also requires, “all employers with hazardous chemicals in their workplaces to have labels and safety data sheets for their exposed workers, and train them to handle the chemicals appropriately.”

1910.1200 - Hazard Communication

The Hazard Communication Standard is under 1910.1200 (subpart Z). The change that has been made to this standard is consistent with the provisions of the United Nations Globally Harmonized System of Classification and Labelling of Chemicals (GHS). The Hazard Communication Page on OSHA has downloadable versions of the 1910.1200 Final Rule and appendices that are updated to align with GHS.

What is the Globally Harmonized System?

According to OSHA the Globally Harmonized System (GHS), “is an international approach to hazard communication, providing agreed criteria for the classification of chemical hazards, and a standardized approach to label elements and safety data sheets. The result of this change and negotiation process resulted in a document entitled, Globally Harmonized System of Classification and Labeling of Chemicals” also known as The Purple Book. The documents provide criteria for the health, physical, and environmental hazards of chemicals, as well as standardized label elements, signal words, and a standardized information safety data sheet.

Why did OSHA modify the Hazard Communication Standard to adopt the GHS?

The fundamental reason why they modified the standard is to improve the safety and health of workers through more effective communications on chemical hazards. The initial standard is performance-oriented, allowing manufacturers to put their information on labels and material safety data sheets in whatever format they choose. The GHS is more effective using a standardized approach. This includes detailed criteria for determining what hazards affect a chemical. According to OSHA, this approach will, “enhance both employer and worker comprehension of the hazards, which will help to ensure appropriate handling and safe use of workplace chemicals.” Adopting GHS will improve all the information that is received from other countries, considering that the US is a major importer and exporter of chemicals, it is more efficient for the labels and safety data sheets to be standardized.

Definitions for the Hazard Communication Standard

According to OSHA, these are key definitions and changes that were recently made to the Hazard Communication Standard:

- Hazard classification: Provides specific criteria for the classification of health and physical hazards, as well as classifications of mixtures.

- Labels: Chemical manufacturers and importers will be required to provide a label that includes a harmonized signal word, pictogram, and hazards statement for each hazard class and category. Precautionary statements must also be provided.

- Safety Data Sheets: Will now have a specified 16- section format.

- Information and training: Employers are required to train workers on the new labels elements and safety data sheets format to facilitate recognition and understanding.

OSHA’s Steps to an Effective Hazard Communication Program for Employers That Use Hazardous Chemicals

- Learn the standard and identity the responsible staff.

- Prepare and implement a written hazard communication program.

- Ensure containers are labeled.

- Maintain safety data sheets.

- Inform and train employees.

- Evaluate and reassess your program.

If you would like to learn more about each step, click here to view OSHA’s recommendations.

Citations

https://www.osha.gov/hazcom/faq

Asbestos Introduction

Asbestos is a hazardous material that needs to be remediated by a professional. According to OSHA, “Asbestos is a naturally occurring mineral fiber. It was used in numerous building materials and vehicle products for its strength and ability to resist heat and corrosion before its dangerous health effects were discovered.” Asbestos fibers are so small; the human’s naked eye cannot see them; therefore, workers are at increased risk. The mineral fibers include chrysotile, amosite, crocidolite, tremolite, anthophyllite, actinolite.

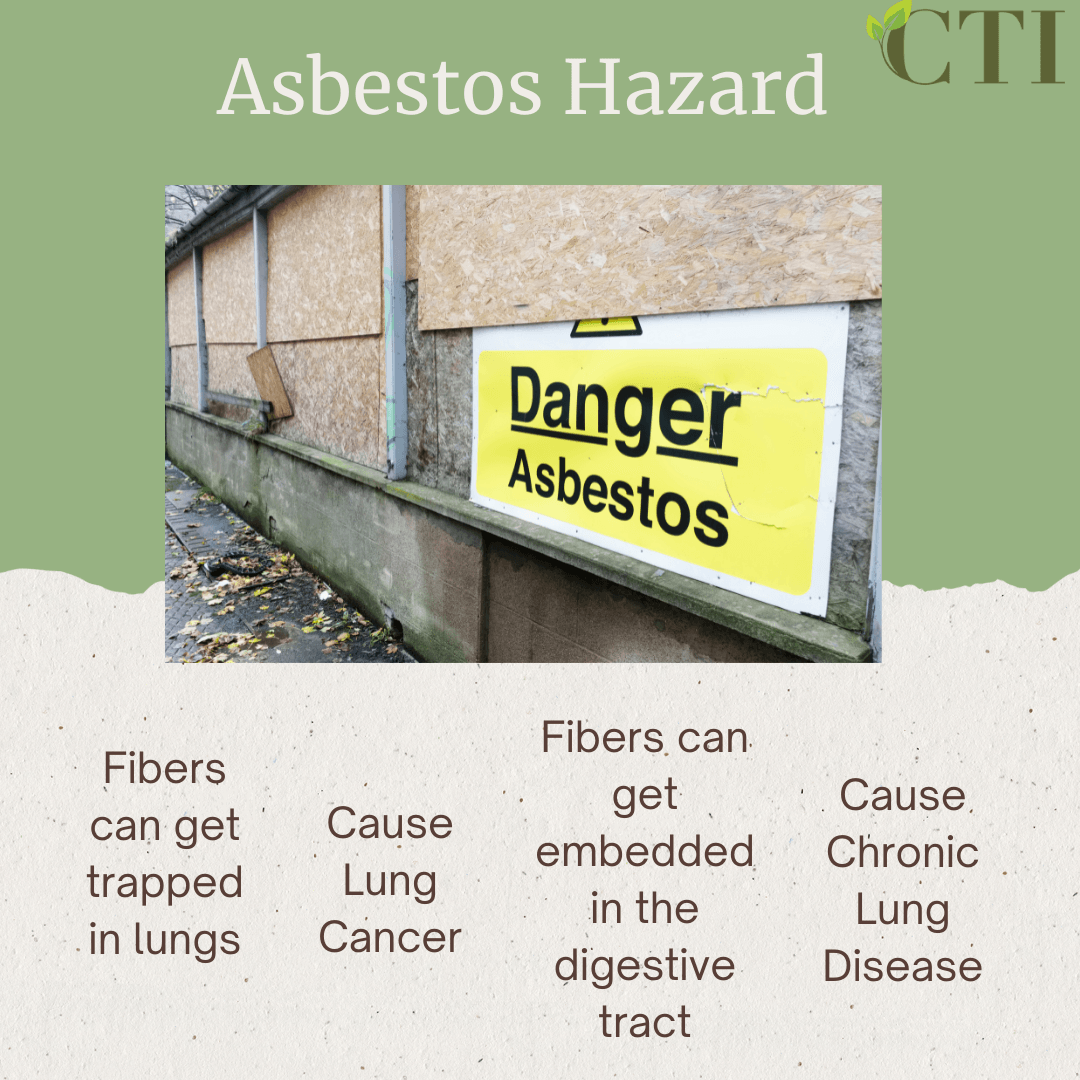

Asbestos Hazards

Asbestos fibers are hazardous when they are released and distributed by asbestos-containing materials. When Asbestos gets distributed in the air and inhaled in and trapped in the lungs. If it is ingested, the asbestos fibers can be embedded into the digestive tract. When this happens, it will cause chronic lung disease as well as lung cancer and other cancers.

According to OSHA, “The hazard may occur during manufacturing of asbestos-containing products; performing brake or clutch repairs; renovating or demolishing buildings or ships; or cleanup from those activities; contact with deteriorating asbestos-containing materials and during cleanup after natural disasters.” Before 1981 some materials contained Asbestos, such as:

- Thermal system insulation

- Roofing and siding shingles

- Vinyl floor tiles

- Plaster, cement, putties, and caulk

- Ceiling tiles and spray-on coatings

- Industrial pipe wrapping

- Heat-resistant textiles

- Automobile brake linings and clutch pads

OSHA standards

- General Industry: 29 CFR 1910.1001 covers work in general industry, such as exposure during brake and clutch repair, maintenance work, and manufacture of asbestos-containing products

- Shipyards: 29 CFR 1925.1001 covers construction, alteration, repair, maintenance, renovation, and demolition of structures containing Asbestos during work in shipyards

- Construction: 29 CFR 1926.1101 covers construction, alteration, repair, maintenance, or renovation and demolition of structures containing Asbestos

Reduce the hazards of Asbestos

According to OSHA, “The standards listed above reduce the risk of workers by requiring that employers provide personal exposure monitoring to assess the risk and hazards awareness training for operations where there is any potential exposure to asbestos.” When exposure occurs, employers are responsible for protecting the working by establishing regulated areas, controlling work practices, and developing engineering controls to reduce the airborne levels. The employers are also responsible for using administrative rules and providing personal protective equipment to all staff.

Asbestos Inspection

The inspection begins with a visual analysis of the affected building or material. Depending on the regulation, there will be a number of samples taken from each material. This process can take hours to a couple of days, depending on the size of the building being tested. After samples are taken it goes to the laboratory to be analyzed. Part of the inspection entails extracting small pieces of material from the building. AS we have learned above there are many materials that were built with asbestos and need to be tested today. After all samples are taken, a report will be written. If the asbestos levels are large, removal of asbestos may be required.

Citations

https://www.osha.gov/sites/default/files/publications/OSHA3507.pdf

https://www.airpf.com/blog/2019/may/what-to-expect-during-asbestos-inspection/

What is IIPP?

IIPP stands for Injury and Illness Prevention Program (IIPP) and is a comprehensive workplace safety plan. Title 8 of the California Code of Regulations section 3203 states that every employer must develop and implement a proper IIPP. By doing so, this document will advance the company's safety and health in the workplace and reduce costs by appropriate management and employee participation.

Why IIPP is Critical for your Business

If you do not have a properly written IIP, your business can face penalties and jeopardize the health of your employees. An updated IIPP will educate your employees regarding health or safety hazards in the workplace. If a random inspection from Cal/OSHA happens and your business does not have an IIPP, you will be issued a regular penalty. COVID-19 has created health hazards in every workplace; therefore, every workplace must have an IIPP.

8 required elements for an IIPP according to the California Department of Industrial Relations:

- Responsibility

- Have your management’s support

- Be knowledgeable about your workplace's health and safety issues and hazard control measures

- Have the authority and responsibility for making the necessary corrections and implementing them in the program

- Compliance

- Establish a system for ensuring that employees follow the organization’s safety rules

- Your system cannot discourage employees from reporting their injuries or symptoms

- Periodically review and update all rules and procedures to make sure they reflect the present conditions at your workplace.

- Communication

- Communicate in a way that is easily understandable by all affected employees on matters relating to workplace safety and health

- All employees must be informed about your IIPP and how it is going to be implemented, and their responsibilities to comply with the program

- Your communication should include provisions for encouraging employees to report potential hazards in the work environment without fear of reprisal

- Management must be present at the meetings

- Hazards assessment

- Your workplace must have procedures in place to identify and evaluate all areas of the work environment for health and safety hazards, unsafe conditions, and work practices

- Accident/exposure investigation

- Employers need a procedure in place to investigate occupational injuries and illnesses

- This is critical for accident prevention and controlling losses at the workplace

- Hazard correction

- When hazards are observed, they should be addressed in a timely manner

- Employees necessary to correct the hazardous condition shall be provided the necessary safeguards

- Training and instruction

- Training allows employees to learn their roles properly, brings ideas to the workplace, reinforces existing ideas and practices, and puts the program into action

- The IIPP standard requires that training be provided to all workers on the hazards in the workplace when they start working for their employer, whenever they are given a new job assignment, and whenever new procedures and equipment are introduced

- Recordkeeping

- Workplaces must maintain a written IIPP and documentation of how the elements of their IIPP are carried out

- Scheduled and periodic inspections to identify unsafe conditions and work practices, these records must include:

- The name and persons conducting the inspection

- The hazards identified

- The action taken to correct the unsafe hazard and/or work practices

To read more about these 8 elements of an IIPP go to https://www.safeatworkca.com/safety-articles/what-is-an-iipp/

Examples of IIPP from Cal/OSHA

- CS 1A - Workplace Injury and Illness Prevention Model Program for High Hazard Employers

- CS 1B - Workplace Injury and Illness Prevention Model Program for Non-High Hazard Employers

- CS 1C - Workplace Injury and Illness Prevention Model Program for Employers with Intermittent Workers

Consulting Services

If your business needs to help develop or improve your IIPP, CTI Environmental, Inc. can create one for you. We will identify actual and potential safety or health hazards in the workplace and solutions to control them, provide a written report summarizing the findings, and interpret applicable safety and health standards. If you are interested in consulting services, email info@ctienviro.com or call 562.608.8401.

CITATIONS

https://www.safeatworkca.com/safety-articles/what-is-an-iipp/

https://www.dir.ca.gov/chswc/woshtep/iipp/

What is the definition of an Active Shooter

According to the FBI, an active shooter is “an individual actively engaged in killing or attempting to kill people in a populated area, and recent active shooter incidents have underscored the need for a coordinated response by law enforcement and others to save lives.”

History of Active Shooter

There have been a total of 277 active shooter incidents from the year 2000 to 2018 in the United States. From those 277 incidents, 884 victims were killed and 1,546 wounded. The graphic below from fbi.gov shows the increase in active shooters over 18 years in the United States.

As a business owner, you probably look for ways to save money where you can. One of these might be to invest in new-to-you commercial or industrial equipment to help keep your business moving without a huge price tag. Before you lay down your cash, there are some important things to consider. A few of the most critical are:

If the seller is reputable.

It is possible to find virtually anything you want online these days. Unfortunately, because of the anonymous nature of the internet, not all sellers actually have good intentions. The last thing you want is to spend your hard earned money on equipment that is too weary to do the job, missing parts, or otherwise defunct.

Before you contact an individual or company with whom you do not have an established relationship, do your homework. Check public records and websites that are dedicated to consumer problems. You can also search the Better Business Bureau to see if the company is listed with any trade organizations and read their reviews.

The shape of the equipment.

Not all equipment is created equally. Depending on what you're buying, you might be able to find a bargain on a piece of machinery that still has lots of life left. Stamping Journal notes that things like stamping tools can take years’ worth of abuse before needing any major repairs. Purchased used, this type of equipment may only need a quick tune-up and to have their nameplate replaced.

Name plates are crucial because they contain safety warnings, equipment data, and other pertinent information. Choose a heavy-duty brand that won't fall off in harsh warehouse conditions or with use and handling.

Keep in mind that printers and other office equipment may only have a functional lifespan of two to four years. Anything older than this might not be worth the price, even if it’s used.

Whether or not you can see it in person.

If a seller insists on taking money upfront before you’ve had a chance to inspect the equipment , run! Chances are you’re in for trouble. Ideally, you’re invited to see the equipment in action so that you can evaluate its capabilities in a real-world environment.

Does the equipment have a clear title?

Depending on what you are buying, your equipment may be titled. This means there is a paper trail that follows it from production to the marketplace and shows ownership at all stages of its life. If you are interested in a non-titled piece of machinery, First Capital Business Finance recommends asking for a proof of purchase and proof that the original loan has a zero balance. If the seller still owes money, the title cannot be transferred without paying it off.

Where to buy business equipment

For industrial machinery (and some office equipment), your best bet is to look for similar local establishments that are going out of business. But for everything else, marketplaces , such as Amazon, eBay, and Aucto are great options. You can also look around for companies that broker these types of transactions. Gator Chef recommends signing up for a dealer email list if you’re searching for used restaurant equipment.

Finding help

You may find that your business may need additional help installing or running your recently purchased equipment. Here are a few professionals that can help:

● An electrical engineer can provide expertise in anything from electrical motors to communication systems, including computers, robots and consumer electronics. An experienced electrical engineer may command higher fees but also work faster, have more-specialized areas of expertise, and deliver higher-quality work, whereas a contractor still building a client base may price their services more competitively.

● An IT professional can install and build hardware for computer systems.

● A warehouse manager will fully understand how to utilize warehouse equipment efficiently and effectively.

Utilizing a payroll and time-tracking system for your construction crew is important too, and not just for ensuring everyone is paid on time. A solid system geared toward payroll for construction crews and other off-site staff boosts worker accountability and makes it easier to determine more approximate project costs. Your crew also has the added benefit of being able to track their time and compensation through a mobile app.

Only you know what your business needs and what you can afford. Buying used is always a risk, but it is one that might be worth taking if you do your homework and get a great deal. But be smart about the process. Always inspect machinery and, just as importantly, verify that your dealer won’t leave you holding a pile of over-used nuts and bolts.

Maintaining safety and compliance is more critical than ever, and CTI Environmental Construction Safety is here to help. Visit our website today to check out our range of services.

What Causes Air Pollution

According to NASA, air pollution is "solid and liquid particles - called aerosols - and certain gases end up in our air." These particles that cause air pollution come from chemical reactions, burning fossil fuels, car exhaust, factories, and wildfires. Air pollution arises from natural and human activity. The human activity impact contributes much more than natural sources. 5 major human activities are the cause of air pollution, which are:-

Transportation - Fuel combustion from cars and vehicles

-

Heat and power generation - oil and coal power plants

-

Industry facilities - manufacturing factories, mines, oil facilities

-

Agricultural waste sites and waste incineration

-

Residential - cooking, heating, lighting, and polluting fuels

A significant factor that contributes to air pollution is urban planning. Los Angeles is an excellent example of this issue. Human sprawl causes people to be more dependent on vehicle transportation which contributes to transportation emissions. If you are interested in learning about urban sprawl and the adverse effects on the environment, read Green Metropolitan by David Owen.

Human activities that contribute to air pollution have gotten out of hand, and the government has to get involved. That is when the Clean Air Act of 1970 was put forth into action. Although this Act does not have solutions for every issue, it is a start to get to where we should be in hopes to reduce our greenhouse gas emissions, have our communities live healthier lives, keep our economy stable, reduce the rising of the sea, and many more.

Types of Air Pollution

There are six types of air pollutants according to WHO:

- Particulate matter: Particulate matter (PM) are inhalable and respirable particles composed of sulfate, nitrates, ammonia, sodium chloride, black carbon, mineral dust, and water.

- Black Carbon: Black carbon is a significant component of PM 2.5 and a driver of climate change, also known as a “short-lived climate pollutant.” Black carbon is one of the largest contributors to global warming after Carbon Dioxide.

- Ground-level ozone: Ground-level ozone is one of the major components of photochemical smog and a critical health risk linked to breaking problems, asthma, reducing lung function, and respiratory disease. It is a secondary pollutant, meaning that it is not directly emitted.

- Nitrogen dioxide: Nitrogen dioxide, mainly emitted by power generations, industrial and traffic sources, is an essential constituent of particulate matter and ozone. There is growing evidence that, independently, it can increase bronchitis and asthma symptoms and lead to respiratory infections and reduced lung function and growth.

- Sulfur dioxide: Sulfur dioxide is primarily produced from the burning of fossil fuels (coal and oil) and the smelting of mineral ores that contain sulfur. Exposure to sulfur dioxide affects the respiratory system and function of the lungs and causes irritation of the eyes.

- Carbon Monoxide: Carbon monoxide is a colorless and odorless gas, which at high levels can be harmful to humans by impairing the amount of oxygen transported in the bloodstream to critical organs. New evidence also reveals that long-term exposure to low concentration is associated with a wide range of health effects.

The EPA’s definition of the Clean Air Act is “the law that defines EPA’s responsibilities for protecting and improving the nation’s air quality and the stratospheric ozone layer.” The stratospheric ozone layer is a layer of gas that filters ultraviolet radiation from the sun. This is essential to have in our atmosphere because it reduces the harmful effects of the sun’s radiation. Congress integrated the Clean Air Act into the United States Code as Title 42, Chapter 85.

The EPA has determined a set quality standard for particulate matter, ozone, sulfur dioxide, nitrogen dioxide, carbon monoxide, and lead. These specific standards achieve and maintain air quality specific to their state. Considered in this plan are state emissions that harm air quality. This creates the opportunity to use the best available technology for stationary sources, such as factories and power plants.

Each state is in charge of enforcing a plan to meet specific standards. According to the EPA, “in some states such as California, local air pollution districts work with the state to produce air quality plans. Each state plan also must prohibit emissions that significantly contribute to air quality problems in a downwind state.”

Progress of Clean Air Act

The Clean Air act has successfully lowered six primary pollutants and lowered many toxic pollutants. The EPA has a great chart that shows the health benefits of the Act and the levels of pollutants. See below for the chart.

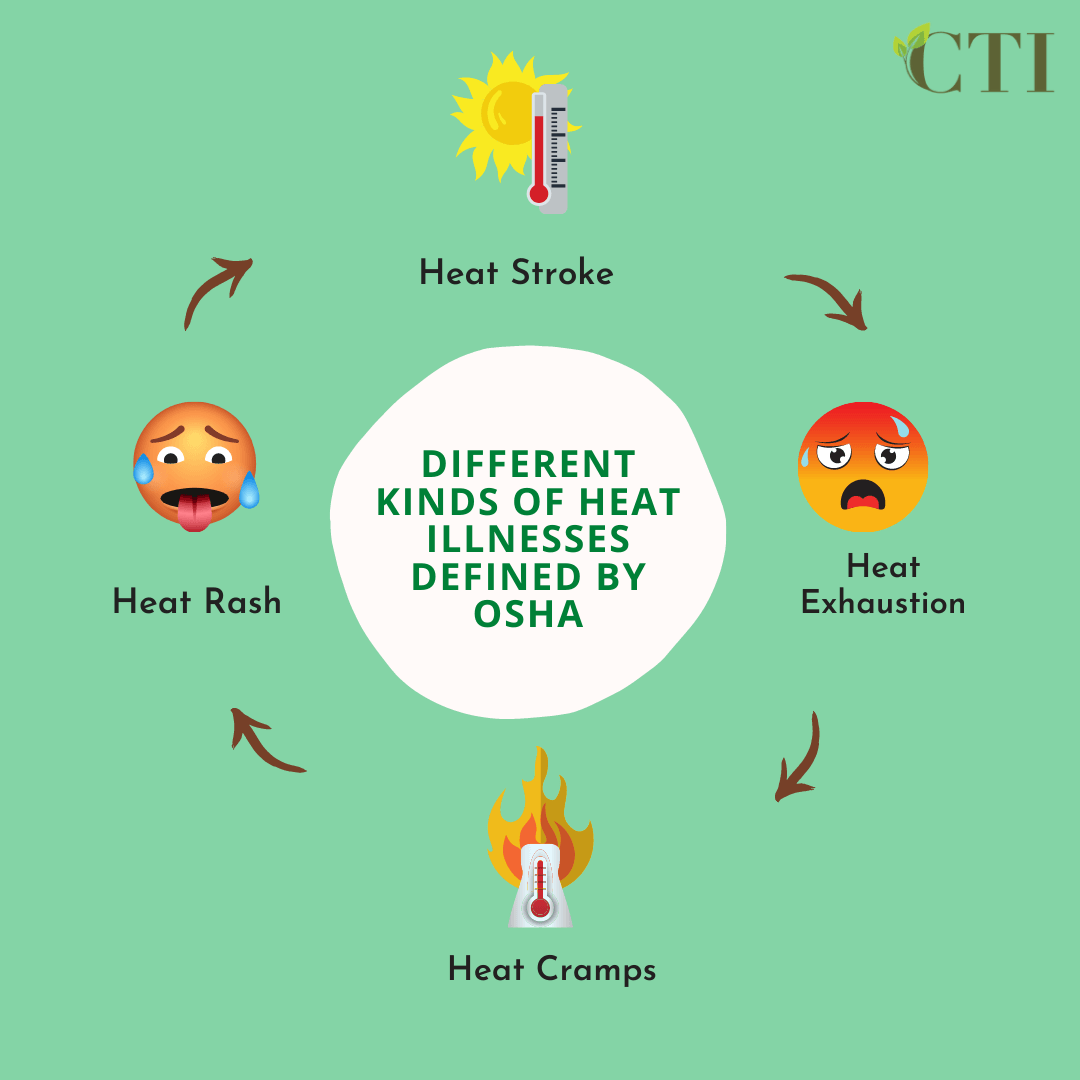

What is a Heat Illness?

According to the CDC, a heat-related illness is when “a warm environment, especially when physically active, the human body relies on its ability to get rid of excess heat to maintain a healthy internal body temperature.” When heat dissipation does not happen quickly, the body temperature will rise, and symptoms will occur, leading to heat illness. Heat illness prevention is when you take the necessary steps, planning, and supervising in a work environment to avoid heat illness.

Signs and Symptoms of Heat Related Symptoms

According to the CDC, an individual can express symptoms and signs that can help prevent a severe heat illness.

Below is a picture the CDC has developed for heatstroke, heat exhaustion, heat cramps, sunburns, and heat rash. This list includes signs and symptoms to look for and what to do if they occur.